The Ultimate Print and Packaging Troubleshooting Guide

Author: Dan Dietrich

“If at first you don’t succeed, keep on sucking till you do succeed” – Curly Howard. Thankfully, we don’t have to be a Stooge by not meeting customer expectations. We can clearly see that the failure to understand common flexographic print issues is costly. The good news: productivity, down press time and excessive waste can be minimized or avoided altogether with a bit of observation and corrective action.

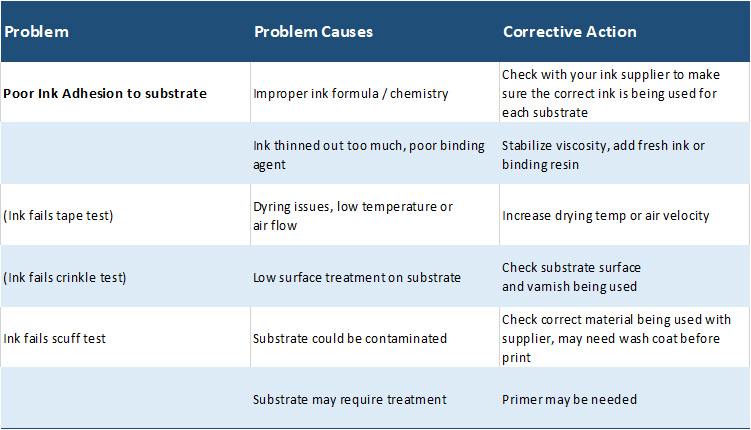

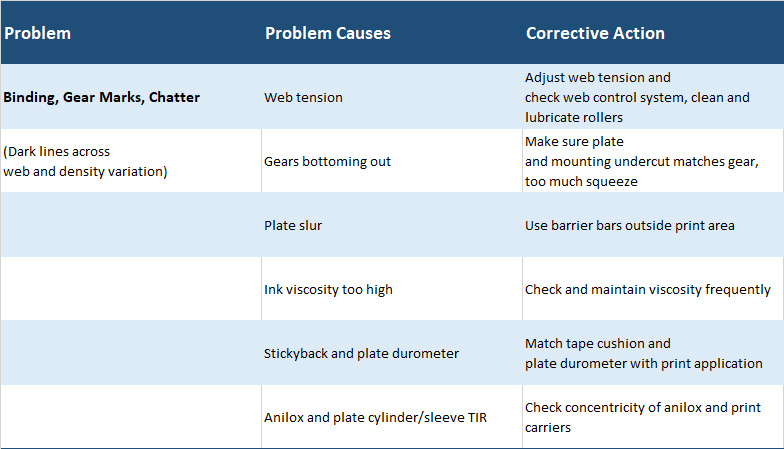

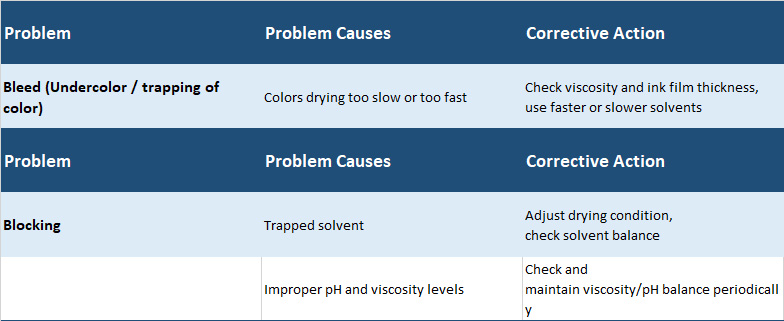

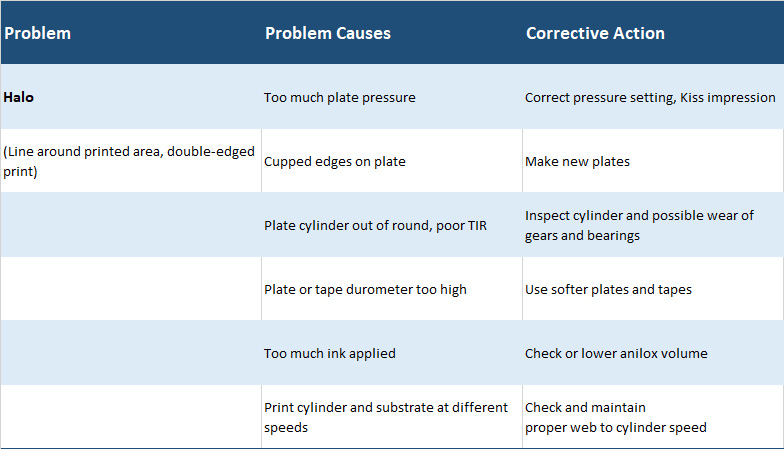

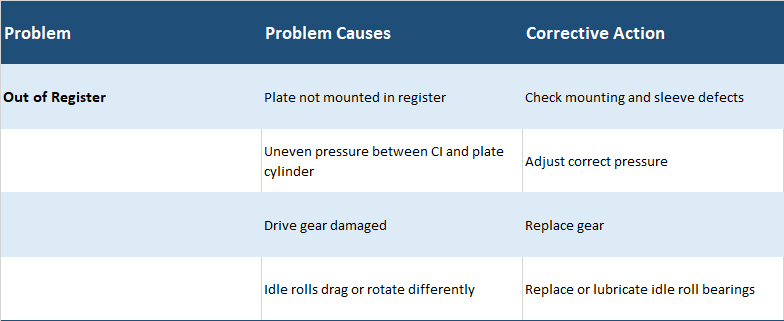

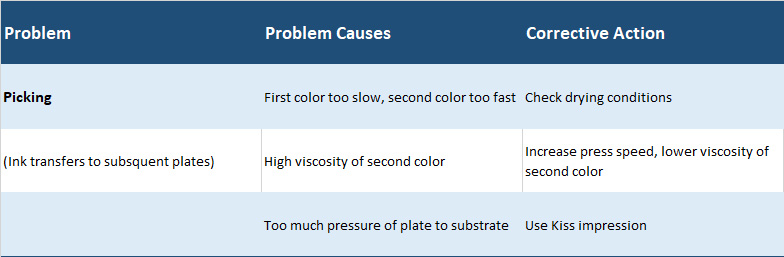

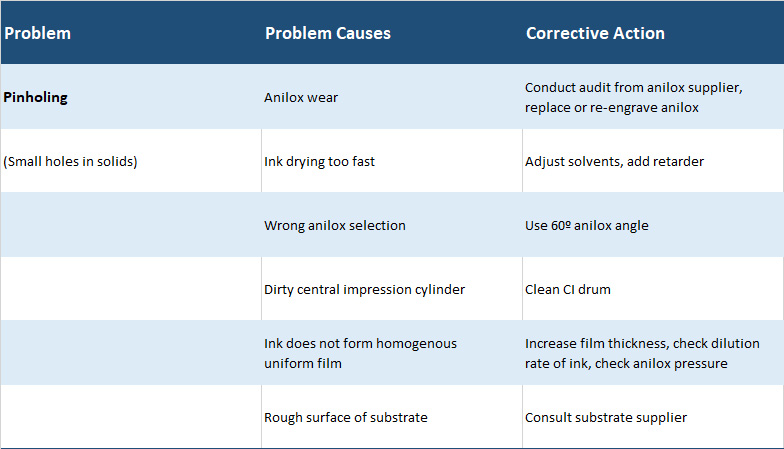

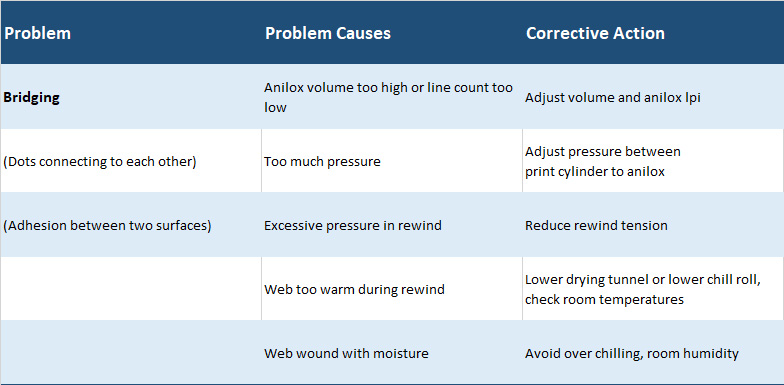

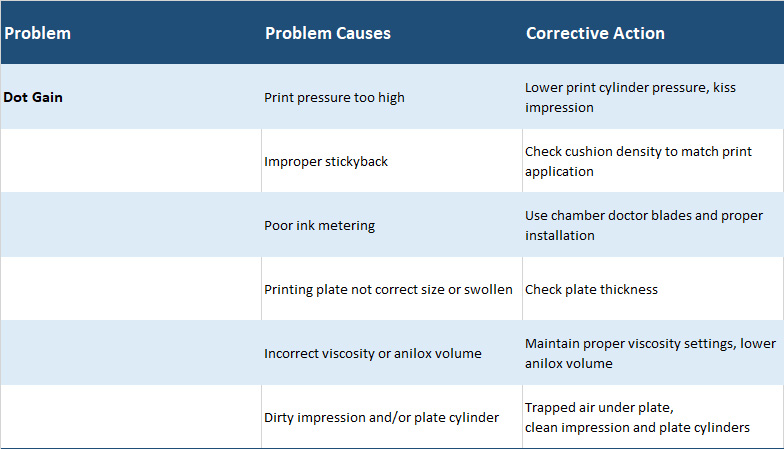

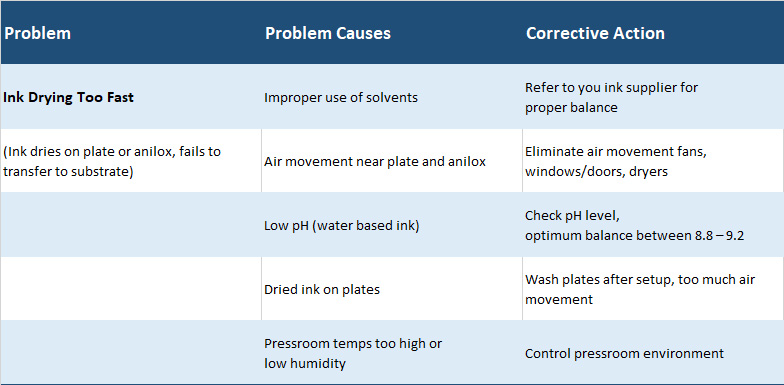

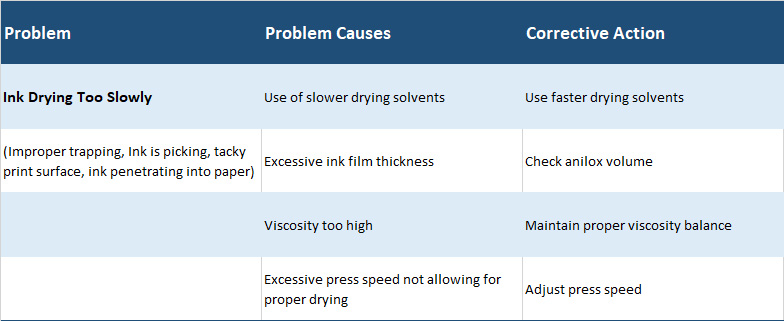

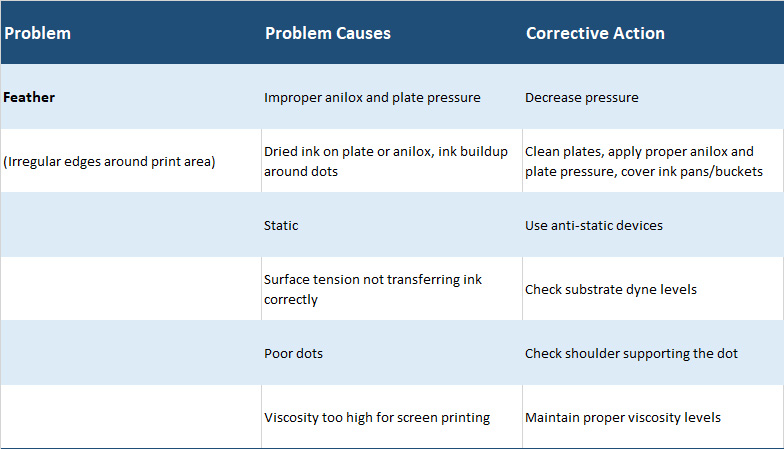

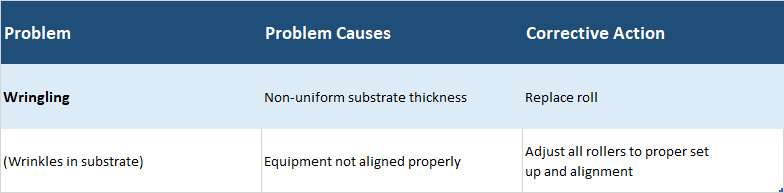

I would like to take the next few pages to lay out many recognized defects and outline their possible causes, as well as point you in the direction of a proper response. While this is not an exhaustive list, I’ve tried to include as many routine issues as I can in a short amount of time. Just think of the following as a troubleshooting guide for common possible solutions spanning a wide range of printing and packaging problems. Let’s get right to it:

Of course, there are many variables in flexo printing and I can’t get into every possible issue here, but in my experience these are the most common problems and they often have very simple solutions. Just remember that when you invite trouble by overlooking maintenance and observation, it is usually quick to adapt, costing you time and money. Don’t wait when it’s so easy to get ahead of the ball before things fall apart!

One last note to leave you with: it’s worthwhile to bring technology and automation into the conversation here because they can assist in monitoring and sustaining your optimal press conditions in hugely impactful ways. For instance, GAMA systems are capable of controlling and automatically maintaining pH, viscosity and temperatures. Grafikontrol can assist in color monitoring, web viewing / print defection, registration and waste management. As a rule of thumb: when in question, it is always best to consult with your suppliers. After all, that’s what we’re here for.