We Know Flexible Packaging

Your success is our success, so we deliver consistency and quality day in and day out. Combining the industry’s most experienced technician and decades of expertise, we are here to support your wide web printing needs from anilox rolls to doctor blades. Our unmatched service standards and personalized support make it possible for you to attain high-quality, high-volume and high-speed printing without compromises.

-

Discover Pamarco’s Wide Web Market:

The demand for creative flexible packaging is on the rise and it’s up to printers to meet the high expectations. Consumers continue to drive the demand for sustainable flexible packaging and brands have almost unlimited graphic design possibilities for creating unique and eye-catching designs. From high-quality food packaging to shopping bags, Pamarco has the knowledge and resources you need to overcome new challenges and stay ahead of the curve. Have a question? Ask us anything.

-

Stay Current on Wide Web Market Trends

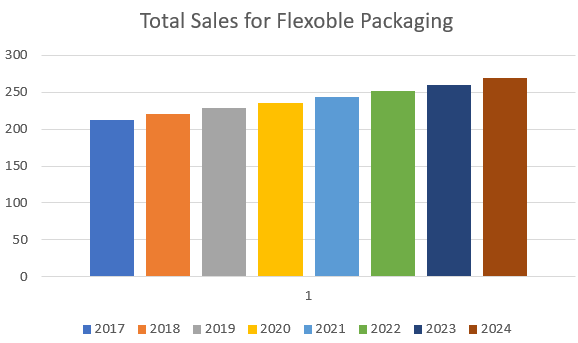

From Packaging Impressions: “According to the research organization Smithers, total sales for flexible packaging worldwide will reach $228 billion in 2019 and grow at an annual average rate of 3.3%, reaching $269 billion in 2024. The FPA says that the flexible packaging industry had $31.8 billion in sales in the U.S. in 2018 and that this volume accounts for 19% of the country’s packaging market overall”

-

Helpful Links

FAQ

Keeping your anilox clean is a major part of extending the life of your roll. We offer a large selection of cleaning chemicals and machines for all types of inks and presses as well as tips and tools to help you get the best clean.

Tips on cleaning

Cleaning solutions

Not sure which cleaning chemicals will work best for your press?

Take our quiz

With the anilox roll being the heart of the printing press, Pamarco has a vast knowledge of ink management and can help ensure your system provides complete color consistency from run to run, across any printing press and substrate. Ink management is a key to ensuring highest productivity and control of cost, consult Pamarco to ensure you’re maximizing performance.

Ink management solutions

Why proofing matters

Ink management tools

Meet Iris: the Goddess of Color

We can clearly see that the failure to understand common flexographic print issues is costly. The good news: productivity, down press time, and excessive waste can be minimized or avoided altogether with a bit of observation and corrective action.

Don’t see the solution you need?

Contact Us.

At Pamarco, we serve many of the industry leaders in wide web film printing. Our years of experience and process standards that produce a more consistent anilox roll give us a great edge. The requirements for this industry are both individual and collective. A single anilox roll must be consistent in TIR, runout, cell volume, and polishing methods. We have process procedures in place that allow us to produce a consistent engraving/volume time after time. We have invested in critical new machinery that has helped us reduce volume variances as well as allowed us to hold industry-leading tolerances. We are constantly evaluating data - before, during, and after the engraving process.

James Carson

Technical Sales